Submersible pump oil is a specialized lubricant designed for waterproofing and cooling pump components. It ensures optimal performance and longevity of submersible pumps.

Submersible pumps play a crucial role in various applications, from draining flooded areas to extracting groundwater and powering fountain systems. These devices operate under challenging conditions, submerged in fluids that can be corrosive or contain debris. Thus, the right type of oil is critical for maintaining the pump’s efficiency and preventing premature wear or failure.

Quality submersible pump oil acts as a barrier against water ingress and reduces the friction between moving parts, leading to smoother operation and reduced energy consumption. By selecting the appropriate lubricant, users can enhance the reliability and durability of their submersible pumps, ensuring they perform effectively for years to come.

Submersible Pump Oil Type

Submersible pump oil plays a critical role in the smooth operation of submersible pumps. This special type of oil lubricates the pump’s components, protects against corrosion, and provides efficient heat dissipation. Choosing the right submersible pump oil type is crucial for pump longevity and optimal performance.

Understanding Submersible Pump Oil Viscosity

Viscosity refers to the thickness of the oil. It’s a key factor in determining the right submersible pump oil type. Oils with higher viscosity ratings can handle more heat and pressure, which are common in submersible pump operations. On the other hand, lower viscosity oils may be more suitable for colder environments or less intense applications.

Synthetic Vs. Mineral Submersible Pump Oils

- Synthetic Oils: Known for their superior performance in extreme conditions. They resist breakdown and last longer.

- Mineral Oils: More cost-effective but may require more frequent changes. They are suitable for less demanding environments.

Environmental Impact And Biodegradable Options

Environmental safety is a priority for many. Biodegradable submersible pump oils minimize the impact on ecosystems. They break down more easily than traditional oils, offering a green solution to pump maintenance.

Food Grade Submersible Pump Oils For Sensitive Applications

Food grade oils are necessary when pumps are used in food production. These oils meet strict safety standards. They ensure that no harmful substances contaminate the food products.

Selecting The Right Brand And Quality

Brand reputation and oil quality go hand in hand. High-quality brands offer oils that provide better protection and efficiency. Users should choose oils with proven performance records to safeguard their equipment.

Submersible Pump Oil Level

Maintaining the correct submersible pump oil level is crucial for the optimal performance and longevity of your pump. This oil serves as a lubricant and a coolant, protecting the pump’s internal components from wear and overheating. Let’s explore the importance of keeping the oil at just the right level.

Importance Of Correct Submersible Pump Oil Level

Ensuring your pump has the right amount of oil is key. The right level keeps the motor cool and prevents friction. Too little oil leads to overheating and damage. Too much oil can cause leaks and may harm the environment.

How To Check Submersible Pump Oil Level

Checking the oil level is simple. Look for the oil inspection window or remove the oil fill plug. The oil should reach the marked level. Use a dipstick if needed. Always power off the pump and follow safety steps first.

Troubleshooting Low Oil Levels In Submersible Pumps

Low oil levels can signal a leak or oil consumption. Inspect for leaks around seals and repair them. If the pump is using oil, it may be time for a maintenance check. Regular checks prevent unexpected issues.

Adjusting Submersible Pump Oil Levels

To adjust the oil, remove the fill plug and add oil slowly. Use only the recommended oil type. Avoid overfilling. Replace the plug securely after reaching the desired level.

Submersible Pump Oil Seal

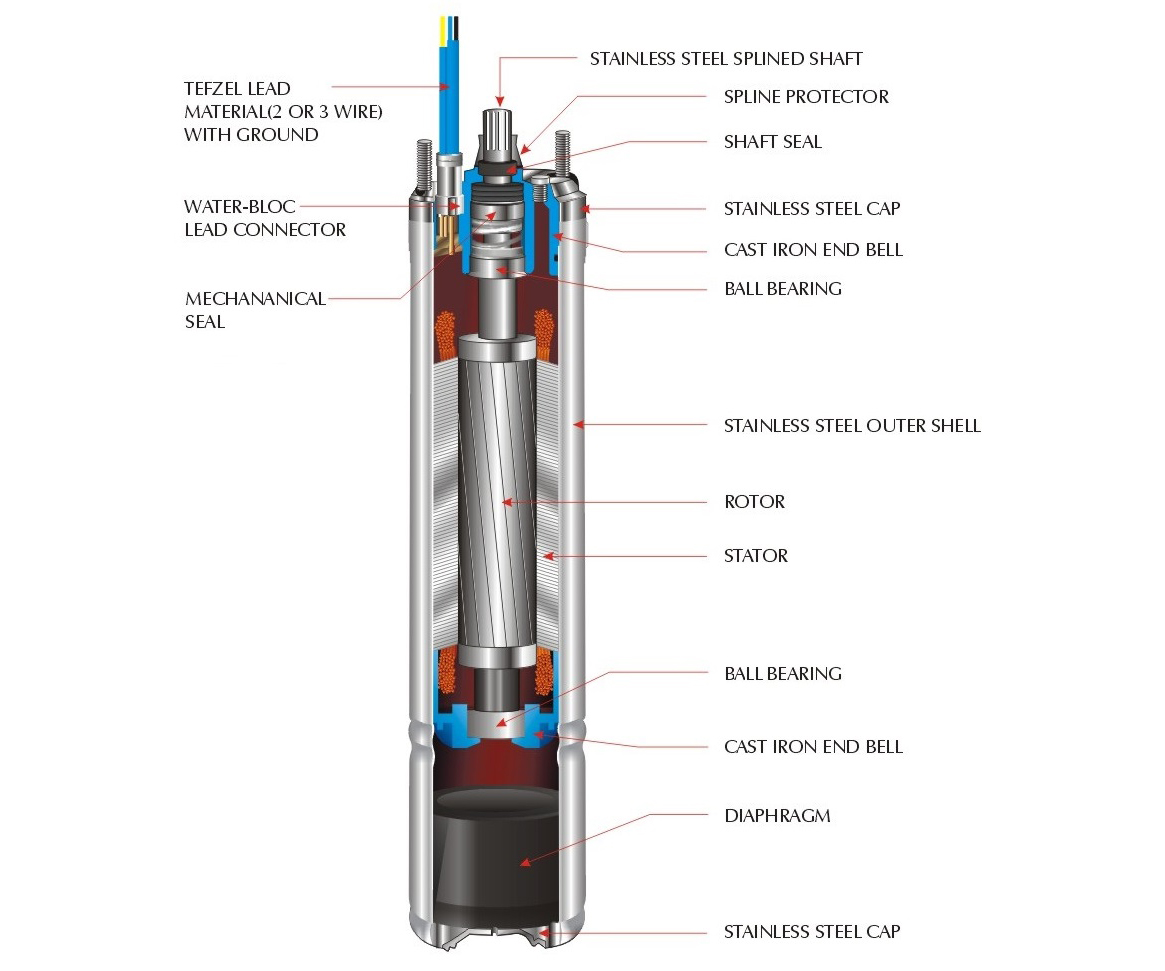

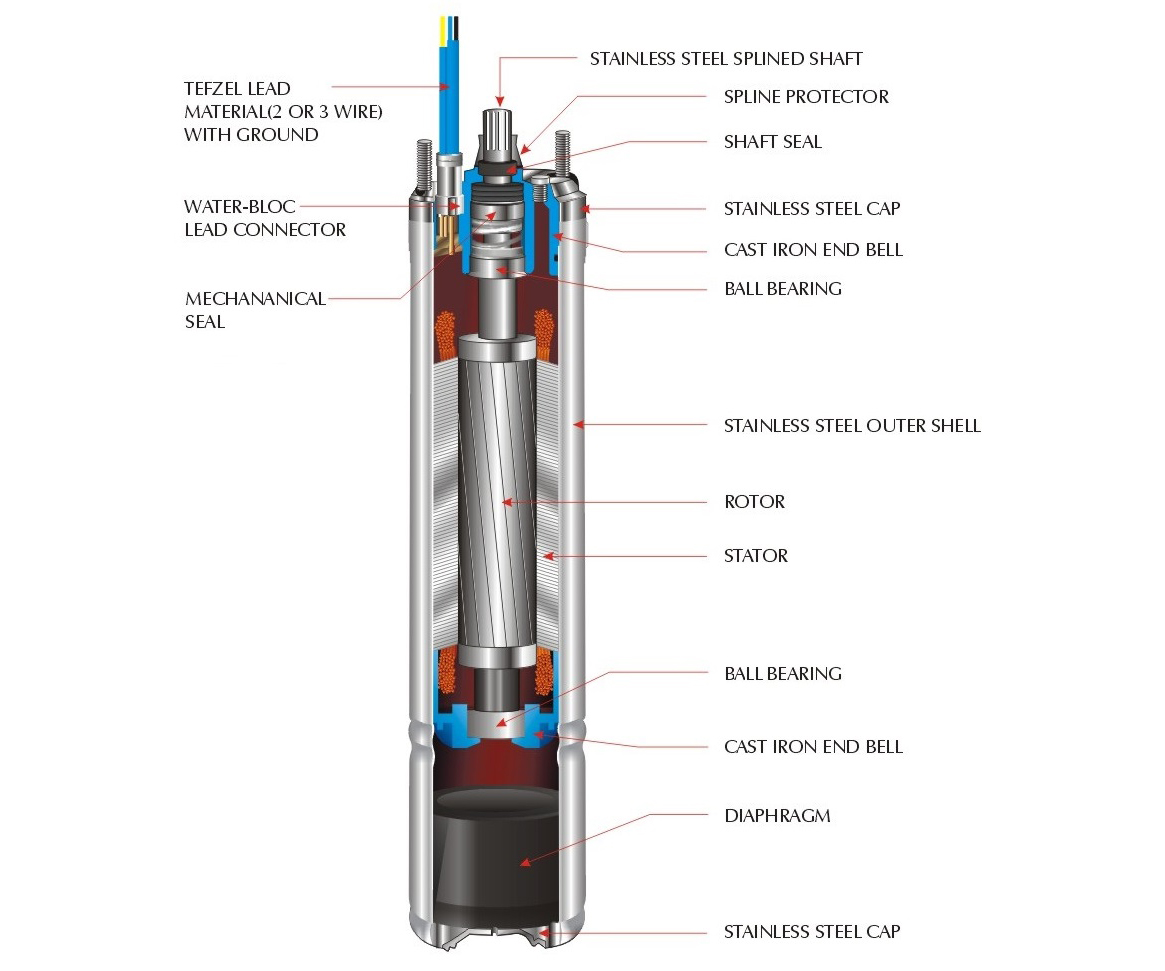

Submersible pumps work tirelessly underwater, and their oil seals play a critical role. These seals keep the oil inside the pump while blocking water and contaminants. A well-functioning submersible pump oil seal is key to the pump’s efficiency and longevity.

The Function Of Submersible Pump Oil Seals

Oil seals in submersible pumps prevent fluid leakage. They maintain a lubricated environment for the moving parts. This protection extends the pump’s life and ensures optimal performance.

Types Of Oil Seals Used In Submersible Pumps

- Mechanical seals – Common in heavy-duty applications.

- Lip seals – Used for smaller, less demanding operations.

- Bellows seals – Offer flexibility and compensate for misalignment.

Materials Used In Submersible Pump Oil Seals

| Material | Properties | Application |

|---|---|---|

| Nitrile Rubber | Oil-resistant and durable | General use |

| Silicone Rubber | High-temperature resistance | High-heat environments |

| Fluorocarbon Rubber | Chemical and heat resistant | Harsh conditions |

Common Issues With Submersible Pump Oil Seals

Seals can fail due to wear, incorrect installation, or material degradation. Regular inspection and maintenance prevent unexpected downtime.

Maintenance Tips For Submersible Pump Oil Seals

- Check seals regularly for signs of wear or damage.

- Clean the seal area to prevent dirt build-up.

- Replace seals with exact specifications to ensure a proper fit.

Submersible Pump Oil Field

Submersible pump oil plays a crucial role in the functioning of submersible pumps, commonly used in various applications such as water wells, oil wells, and irrigation systems. The submersible pump oil field refers to the specific area of expertise focusing on the selection, maintenance, and troubleshooting of the oil used in these pumps. Ensuring the right type of oil, along with regular maintenance, is key to the efficient operation and longevity of submersible pumps.

Types Of Submersible Pump Oil

Different submersible pumps require different types of oil based on their application and design. Here are the most common types:

- Synthetic Oil: Best for extreme temperatures and environments.

- Mineral Oil: A cost-effective option for many standard applications.

- Biodegradable Oil: Ideal for environmentally sensitive areas.

Importance Of Choosing The Right Oil

Choosing the right oil for your submersible pump is essential. The right oil ensures:

- Efficient Operation: Reduces friction and heat, leading to better performance.

- Longer Lifespan: Proper lubrication can significantly extend a pump’s life.

- Environmental Safety: Certain oils are designed to minimize environmental impact.

Maintenance Tips For Submersible Pump Oil

Maintenance is key to keeping your submersible pump in top condition. Follow these tips:

- Regularly check oil levels and quality.

- Change the oil according to the manufacturer’s recommendations.

- Use only the specified type of oil for your pump.

Common Issues And Solutions

| Issue | Solution |

|---|---|

| Oil Leakage | Check and replace seals as needed. |

| Contaminated Oil | Change the oil and clean the pump internals. |

| Incorrect Oil Type | Switch to the correct oil specified by the manufacturer. |

Submersible Pump Oil And Gas

Exploring the depths of the earth, submersible pump oil plays a crucial role in the extraction of oil and gas. This specialized lubricant ensures the smooth operation of pumps submerged in the harshest environments. With the right formulation, submersible pump oil can withstand extreme pressures and temperatures, safeguarding the equipment and optimizing production.

The Vital Role Of Submersible Pump Oil In Extraction

Submersible pumps are essential for drawing oil and gas from deep reservoirs. High-quality submersible pump oil is key to maintain pump performance. It reduces wear and tear, prolongs equipment life, and maintains efficiency under severe conditions.

Selecting The Right Oil For Your Submersible Pump

Choosing the correct submersible pump oil is vital for operation success. Factors include viscosity, thermal stability, and chemical composition. The oil must be formulated to resist emulsification and oxidation, ensuring reliable pump function.

Understanding The Properties Of Submersible Pump Oils

- Thermal Resistance – Submersible pump oils must endure high temperatures without degrading.

- Corrosion Inhibition – These oils contain additives that protect against rust and corrosion.

- High Viscosity Index – A high viscosity index ensures consistent performance across temperature fluctuations.

Maintenance And Monitoring For Optimal Performance

Regular maintenance and monitoring of submersible pump oil levels and quality are imperative. This practice prevents unexpected breakdowns and ensures continuous operation. Technicians should sample the oil periodically for signs of contamination or degradation.

Environmental Considerations In Oil Selection

Environmental impact is a significant factor in oil selection. Operators must choose submersible pump oils that minimize ecological footprints. These oils should be biodegradable and non-toxic to marine life, reducing environmental risks.

Credit: www.framo.com

Submersible Pump Oil Price

Understanding submersible pump oil price is crucial for maintenance and operation. This special oil lubricates and cools submersible pumps, ensuring longevity and efficiency. Prices vary based on oil quality, brand, and quantity. Smart shopping can lead to both cost savings and optimal pump performance.

The Factors Affecting Submersible Pump Oil Prices

Different factors influence the cost of submersible pump oil:

- Oil Type: Synthetic oils generally cost more than mineral-based oils.

- Brand Reputation: Well-known brands might charge more due to their market standing.

- Quantity: Bulk purchases often reduce the per-unit price

Price Comparison Of Popular Submersible Pump Oils

Comparing prices helps in making an informed decision:

| Brand | Type | Price Range |

|---|---|---|

| Brand A | Synthetic | $25 – $50 |

| Brand B | Mineral | $15 – $30 |

| Brand C | Synthetic Blend | $20 – $40 |

How To Find The Best Deals On Submersible Pump Oil

Finding the best price involves a few simple steps:

- Check online marketplaces for competitive pricing.

- Look for sales or discounts at hardware stores.

- Consider purchasing in bulk from wholesalers.

Cost-saving Tips For Submersible Pump Oil Buyers

Save money without compromising on quality:

- Buy in Bulk: Larger quantities often mean lower prices.

- Generic Brands: They can be as effective as premium brands but more affordable.

- Seasonal Deals: Prices may drop during off-peak seasons.

Submersible Pump Oil Change

Changing the oil in a submersible pump is crucial for its performance. This process ensures the pump runs smoothly and lasts longer. It involves draining old oil, cleaning components, and adding fresh oil. Regular oil changes prevent damage and save money in the long run.

Sustainability Initiatives

Adopting sustainable practices in changing submersible pump oil is vital for environmental protection. Manufacturers and users are turning to eco-friendly oils and disposal methods. This shift helps reduce harmful waste and pollution. Here are key initiatives:

- Biodegradable Oils: Many companies now produce oils that break down naturally. These oils lessen the environmental impact if they leak or are disposed of improperly.

- Recycling Programs: Recycling used oil is a powerful way to protect the planet. Specialized facilities can process and reuse oil, preventing it from harming the environment.

- Eco-Friendly Packaging: Reducing plastic use in packaging cuts down on waste. Some brands use recyclable materials or containers made from recycled products.

Below is a table showcasing the benefits of sustainable oil changes for submersible pumps:

| Benefit | Description |

|---|---|

| Reduced Pollution | Biodegradable oils and proper disposal decrease soil and water pollution. |

| Longer Pump Life | Using high-quality, eco-friendly oils can extend the pump’s lifespan. |

| Cost Savings | Recycling oil and efficient use lower long-term maintenance costs. |

By embracing these sustainable initiatives, we can significantly lower the environmental impact of maintaining submersible pumps. This approach not only benefits the planet but also enhances the efficiency and durability of the pumps.

Credit: www.framo.com

Credit: www.formosapump.com.tw

FAQs

When it comes to maintaining your submersible pump, one key component often prompts questions: the oil. From the type used to the amount needed, understanding submersible pump oil is crucial for optimal performance. This section answers frequently asked questions to help you keep your pump running smoothly.

Do Submersible Pumps Have Oil In Them?

Yes, submersible pumps do contain oil. The oil surrounds the motor for cooling and lubrication. It ensures the smooth operation of the pump’s internal components and extends its lifespan.

How Much Oil Goes In A Submersible Pump?

The oil quantity varies based on the pump size and model. Always refer to the manufacturer’s guide to determine the correct amount for your specific pump.

What Oil Is Used In Submersible Pumps?

Submersible pumps typically use a special dielectric oil. This oil is non-conductive and safe for use around electrical components. It’s important to use the recommended oil type to avoid damage.

Which Is Better: Oil-filled Or Water-filled Submersible Pump?

Choosing between oil-filled and water-filled pumps depends on the application. Oil-filled pumps are generally more durable and require less maintenance. Meanwhile, water-filled pumps are often more cost-effective and eco-friendly.

Do You Oil Small Submersible Pumps For Storage?

Small submersible pumps typically don’t require additional oiling for storage. Ensure they are clean and dry before storing to prevent corrosion or damage.

Credit: www.formosapump.com.tw

Credit: www.framo.com

Conclusion

To sum up, selecting the right submersible pump oil is crucial for performance and longevity. Remember, quality lubrication protects and extends the life of your equipment. Always consult with professionals and adhere to manufacturer guidelines for the best results. Keep your pumps running smoothly with the ideal oil choice.