Common well pump pressure switch problems include failure to start or stop the pump and erratic pressure. Symptoms often point to issues with the switch settings or malfunction.

Dealing with a well pump pressure switch can be daunting, especially when water access is interrupted. These switches play a crucial role in regulating water pressure within your home’s plumbing system. They signal your well pump to start or stop pumping water based on the pressure in the system.

When they malfunction, it could lead to low water pressure, no water at all, or even cause the pump to run continuously, risking burnout. Understanding the common problems associated with these switches can save you time and money. Quick identification and resolution of issues ensure a steady and reliable water supply, keeping your household operations smooth and hassle-free. Regular maintenance and awareness of how pressure switches work are key to preventing disruptions in your water supply.

Common Symptoms

Well pump pressure switch problems can disrupt your home’s water supply and cause frustrating issues. Recognizing the common symptoms is key to diagnosing and fixing the problem swiftly. Let’s explore some signs that your well pump pressure switch might be failing.

Low Water Pressure

Low water pressure is a telltale sign of well pump pressure switch problems. This issue can turn daily tasks like showering or washing dishes into a hassle. Causes may vary, from clogged pipes to a failing pressure switch. Look for these indicators:

- Water trickles from taps, rather than flows

- Shower pressure is weak

- Appliances take longer to fill with water

Understanding the cause is crucial. A table to help you troubleshoot:

| Possible Cause | What To Check |

|---|---|

| Clogged Pipes | Inspect for mineral buildup or obstructions |

| Faulty Pressure Switch | Examine switch for damage or corrosion |

| Pressure Tank Issues | Check pressure tank’s air charge and integrity |

If you notice well pump pressure switch problems symptoms like these, it’s best to consult a professional for a thorough inspection and repair.

Frequent Cycling

Frequent cycling is another indicator of a malfunctioning well pump pressure switch. This is when the pump turns on and off more often than usual. It can lead to wear and tear on the pump and even a complete system failure if not addressed. Symptoms include:

- The pump starts and stops rapidly

- A noticeable clicking sound from the pressure switch

- Unexpected changes in water pressure

These issues often stem from various causes, such as:

| Common Cause | Action Required |

|---|---|

| Leaking Pressure Tank | Search for leaks and repair or replace the tank |

| Waterlogged Tank | Drain the tank and reset the air charge |

| Malfunctioning Switch | Replace or adjust the pressure switch settings |

When well pump pressure switch problems no water issue arises, it’s a severe symptom of frequent cycling. Immediate action is necessary to prevent damage to the pump and restore water supply.

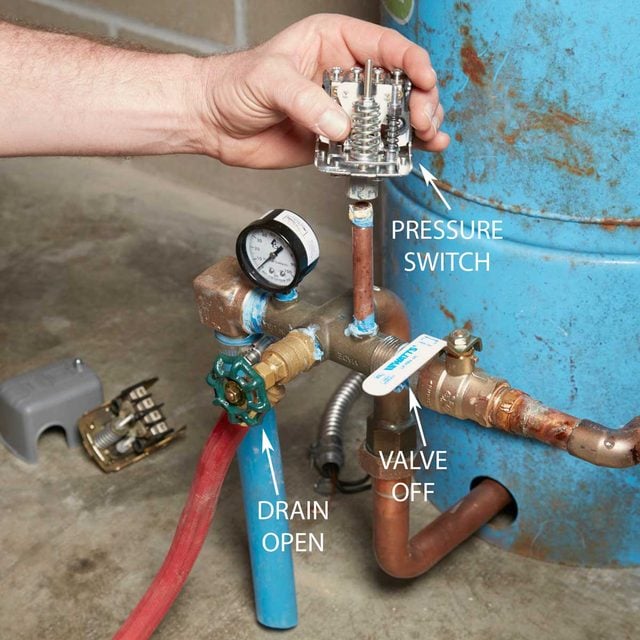

Credit: www.familyhandyman.com

Causes Of Failure

A well pump pressure switch controls the water pressure in your home. It’s a critical piece that turns the pump on and off. Like all parts, it can break down. Knowing what causes these failures can save you time and money. Let’s look at two common culprits: worn contacts and debris buildup.

Worn Contacts

Over time, the electrical contacts within the pressure switch can wear out. This is due to the constant opening and closing as the pump cycles. Worn contacts mean the switch may fail to activate the pump, leading to low water pressure or no water at all. Signs of this issue include a pitted or burnt appearance on the contacts. Here’s what you need to know:

- Continuous Use: The more your system runs, the faster the contacts wear down.

- Electrical Surges: Surges can cause extra stress and heat, speeding up wear.

- Quality of Contacts: Higher quality materials usually last longer.

Check the following table for a quick guide on worn contact indicators:

| Indicator | What It Means |

|---|---|

| Burnt Contacts | Excessive heat or electrical overload has damaged the contacts. |

| Pitted Contacts | Normal wear and tear from repeated use. |

| Stuck Contacts | Contacts are fused together, often from a high current event. |

Debris Buildup

Debris in the pressure switch can lead to malfunctions. This might be sand, sediment, or other particles that find their way into the system. Debris can prevent the diaphragm from moving or clog the inlet port. This causes the switch to read pressure incorrectly or not operate at all. Here are steps to address debris buildup:

- Turn off power to the well pump at the breaker box.

- Release pressure from the system by opening a faucet.

- Inspect and clean the pressure switch components.

- Look for damage that debris may have caused.

Below is a simple breakdown to help you understand the impact of debris:

| Component | Impact of Debris |

|---|---|

| Diaphragm | Cannot flex properly, leading to incorrect pressure readings. |

| Inlet Port | Blockage can stop the switch from activating the pump. |

| Electrical Contacts | Debris can cause insulation, preventing electrical flow. |

Types Of Pressure Switches

A well pump pressure switch is a vital component. It tells your pump when to start and stop water pressure. It ensures steady water flow and pressure in your home. Like any device, it can face issues. Understanding the types of pressure switches helps spot problems early.

Mechanical Switches

Mechanical switches are common in well systems. They rely on physical movements to control the pump. A diaphragm or set of springs reacts to pressure changes. This action opens or closes an electrical circuit. Here are key points about mechanical switches:

- Simple in design and easy to install.

- Cost-effective and widely available.

- Manual adjustments are possible for cut-in and cut-out pressures.

These switches can have problems over time. Such issues include contacts sticking or a faulty diaphragm. Regular maintenance can extend their life. The table below outlines common mechanical switch issues and solutions.

| Problem | Solution |

|---|---|

| Stuck Contacts | Clean or replace the contacts. |

| Faulty Diaphragm | Check and replace if needed. |

| Pressure Misreads | Adjust cut-in and cut-out levels. |

Digital Switches

Digital switches are a newer technology. They use electronic sensors and circuits to monitor and manage pressure. Here’s what makes them stand out:

- Accurate pressure control with digital precision.

- Programmable settings for specific needs.

- LED displays for easy monitoring.

While they offer advanced features, digital switches have cons. They can be more expensive and require a power source. Also, they may need a professional for troubleshooting. Below is a quick guide to common digital switch issues and fixes.

| Issue | Fix |

|---|---|

| Sensor Failure | Replace the sensor unit. |

| Display Errors | Reset or update the system. |

| Complex Programming | Refer to the manual or contact support. |

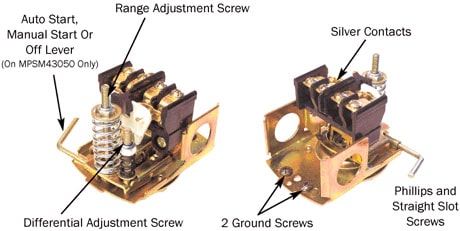

Credit: www.pumpproducts.com

Checking Pressure Settings

Well pump pressure switch problems can be a real headache. They stop water flow or make it too weak. To fix this, checking pressure settings is key. It’s about finding the right balance. Too low, and water dribbles out. Too high, and pipes might burst. Let’s dive into how to adjust these settings properly.

Adjusting The Cut-in Pressure

First, let’s tackle the cut-in pressure. This is when the pump starts. A too low cut-in means your water might stop when you need it most. Too high, and your pump works too hard. Here’s how to set it right:

- Turn off power to the pump. Safety first.

- Find the pressure switch. It’s usually on the pipe from the well.

- Open the cover. You’ll see two nuts. One is for cut-in pressure.

- Using a wrench, turn the nut clockwise to increase pressure. Or, turn it counterclockwise to decrease.

- Adjust little by little. Each turn changes the pressure slightly.

After adjusting, test the water flow. Make sure it starts at the right moment. If not, adjust again.

Adjusting The Cut-out Pressure

Next, let’s look at the cut-out pressure. This is when the pump stops. Setting this right stops the pump from overworking. Here’s what to do:

- Power off the pump again. Always play it safe.

- Locate the second nut on the pressure switch. This one controls the cut-out pressure.

- To increase the cut-out pressure, turn the nut clockwise. To decrease, turn it counterclockwise.

- Make small adjustments. Check the water stops at the pressure you want.

Remember, the goal is a smooth and consistent water flow. Get these settings right, and you’re all set!

Testing The Switch

Well pump pressure switches control your home’s water pressure. Like any device, they can falter. Testing the switch ensures your water system runs smoothly. Let’s dive into how you can check if your switch has a problem.

Using A Multimeter

Testing a well pump pressure switch with a multimeter is a sure way to know if it’s working. Follow these steps:

- Turn off power: Safety first. Cut power to the pump.

- Remove cover: Take off the switch’s cover to expose the wiring.

- Set multimeter: Set your tool to measure resistance or continuity.

- Test contacts: Touch the probes to the terminals. A good switch shows zero or near-zero resistance when closed.

Here’s a table showing what your multimeter readings might indicate:

| Multimeter Reading | Switch Condition |

|---|---|

| 0 Ohms | Good: Switch is closed, conducting electricity. |

| OL (Over Limit) | Bad: Switch is open, no continuity. |

Remember, a reading that fluctuates or shows high resistance suggests a problem. The switch may need cleaning or replacing.

Inspecting For Corrosion

Corrosion can cause major issues with pressure switches. Here’s what to look for:

- Visual check: Look for rust or white, green powdery substances on the terminals and wires.

- Touch test: Gently poke the wires. Crumbly or brittle wires mean corrosion has taken hold.

- Clean up: If there’s minor corrosion, a wire brush can clean the terminals.

Corrosion can be subtle. Even a small amount can disrupt electrical flow. Here’s a simple guide to what you might find and what to do:

| Corrosion Type | Action Needed |

|---|---|

| Light Surface Rust | Clean with a wire brush. |

| Green/White Powder | Remove with electronic cleaner. |

| Severe Corrosion | Parts may need replacing. |

Deal with corrosion quickly. It can spread and cause more damage, leading to switch failure. Regular checks help catch problems early, keeping your water running right.

Common Repairs

Well pump pressure switch problems can leave you without water or cause poor water pressure. Knowing the common repairs helps get your system back on track quickly. Let’s explore the steps to fix two typical issues: replacing the switch and cleaning contacts. These methods ensure steady water flow and proper switch operation. Remember, safety first: always turn off the power before working on your well pump system.

Replacing The Switch

A faulty switch might need a replacement. Follow these steps to install a new one:

- Turn off the power supply to the pump.

- Remove the cover of the switch.

- Note the wiring and take a picture for reference.

- Disconnect wires from the old switch.

- Unscrew the switch from the mounting pipe.

- Wrap plumber’s tape around the threads of the new switch.

- Attach the new switch and tighten securely.

- Reconnect the wires as they were before.

- Put the cover back on.

- Restore power and test the system.

If problems persist after replacing the switch, consider how to reset the pressure switch on a well pump. This can often clear any remaining issues and restore proper function.

Cleaning Contacts

Dirty contacts can cause pressure switch failure. Clean them with these steps:

- Power off the pump and remove the switch cover.

- Inspect the contacts for signs of burning or pitting.

- Use a contact cleaner or fine sandpaper to clean the contacts.

- Reassemble the switch and power on the pump.

To ensure the issue is with the contacts, how to test a pressure switch on a well is crucial. Use a multimeter to check for continuity. If the reading shows an open circuit when the switch is on, the contacts are likely the problem.

Regular maintenance, including cleaning contacts, helps avoid sudden pressure switch problems. It ensures a consistent water supply and prevents larger issues with your well system.

Preventive Maintenance

Well pump pressure switch problems can cause big headaches. Preventive maintenance is key. It keeps your water flowing smoothly. This guide helps you avoid common issues.

Regular Inspections

Checking your well pump and pressure switch regularly is crucial. It spots problems early. Here’s what you should do:

- Look at the pressure switch. Check for damage or rust.

- Listen for strange noises. They signal trouble.

- Test the pressure. Make sure it’s steady.

Keep a log of inspections. Note any changes or repairs. This helps track the pump’s health. Use the table below for a quick guide:

| Date | Observation | Action Taken |

|---|---|---|

| 01/01/2023 | No visible damage, pressure stable | None |

| 03/01/2023 | Minor rust on switch | Cleaned and monitored |

Regular checks prevent big problems. They keep your system running well.

Proper Water Filtration

Good water filtration protects your pump and pressure switch. Hard water and debris hurt them. Here’s how to keep things clean:

- Install a water softener. It stops scale buildup.

- Use sediment filters. They catch dirt and sand.

- Change filters often. Clogged filters cause issues.

Think about your water quality. Test it once a year. This shows if your filters work. If you find a lot of minerals or sand, your system needs better filters. Clean water means a healthy pump and switch.

Remember, good filtration extends your system’s life. It saves money on repairs. Make sure your water is clean.

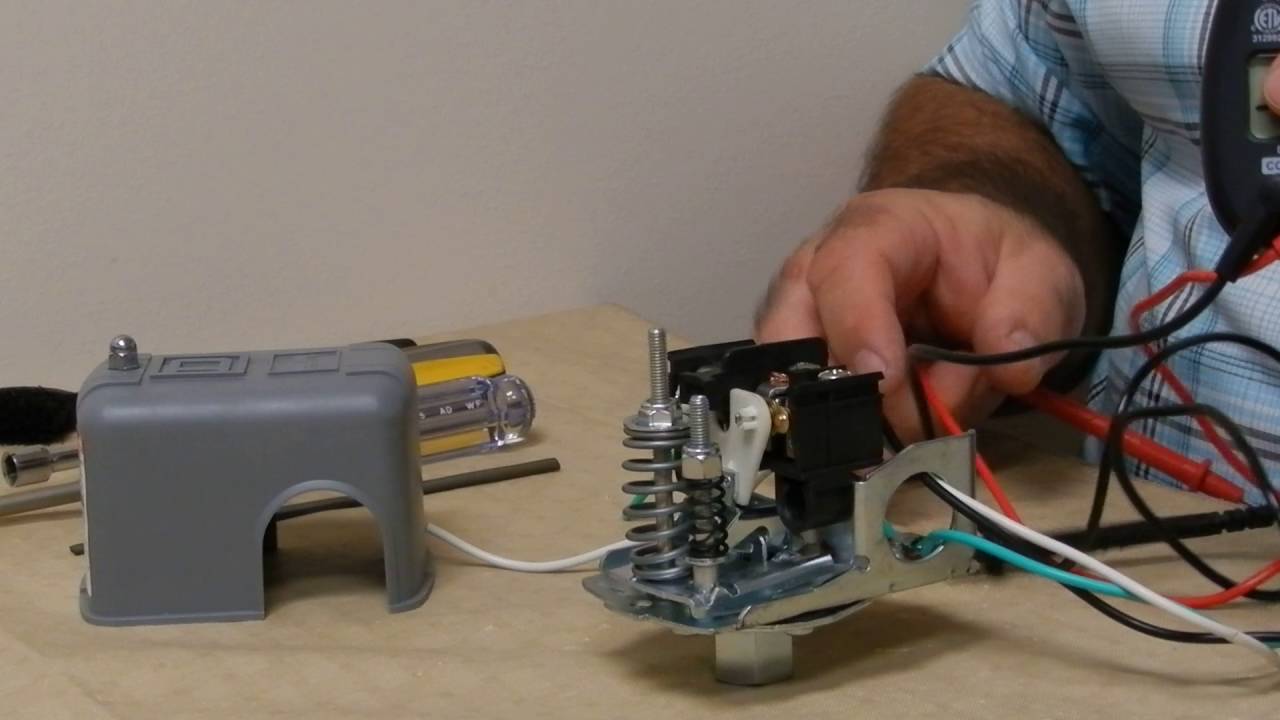

Credit: www.youtube.com

When To Call A Professional

Having a well pump pressure switch means you can enjoy a steady water flow in your home. But sometimes, things go wrong. Your faucets might start sputtering, or you notice the water pressure is just not right. These are signs of pressure switch problems. Knowing when to call a professional can save you time and prevent further damage to your well system.

Persistent Issues

If you’ve tried basic troubleshooting and the problem persists, it’s time to call in the experts. Here are some signs that you need professional help:

- Water pressure is inconsistent: If the water pressure is sometimes high and sometimes low, there might be an issue.

- No water at all: This could mean the switch isn’t communicating with the pump.

- Pump cycles on and off: If the pump turns on and off rapidly, the pressure switch might be failing.

Let’s break down the issues further:

| Issue | Possible Cause | Action |

|---|---|---|

| Short Cycling | Switch can’t maintain pressure | Contact a professional |

| Noisy Pipes | Air in the system or failing switch | Get a professional inspection |

| Water Hammer | Quick closing of valves | Professional can install arrestors |

Complex Systems

Well systems can be complicated. When the pressure switch is part of an intricate setup, it’s best not to tackle the issue alone. Here’s why:

- Electrical hazards: Pressure switches involve electricity. Mistakes can be dangerous.

- Specialized tools: Some repairs need specific tools that professionals have.

- System knowledge: Professionals understand how different parts work together.

Consider these complex aspects:

| Complex Aspect | Reason for Professional Help |

|---|---|

| Variable Frequency Drives (VFD) | Requires precise calibration |

| Multiple Pressure Tanks | Setup is intricate |

| Integrated Control Systems | Complex diagnostics needed |

Don’t risk damaging your system or hurting yourself. Reach out to a licensed technician for any complex pressure switch issues.

FAQs

Dealing with a well pump can sometimes feel like a tricky puzzle. One common piece of this puzzle is the pressure switch, a vital component that controls the water pressure in your home. Have questions about well pump pressure switch problems? You’re not alone! Many homeowners share similar concerns. Below, we tackle the most frequently asked questions, providing clear and simple answers that will guide you through troubleshooting and maintaining your well pump pressure switch.

How Do I Know If My Well Pump Pressure Switch Is Bad?

Recognizing a faulty pressure switch is crucial for maintaining your well pump’s performance. Signs include:

- Erratic water pressure throughout your home.

- Cycling on and off of the pump too frequently or not at all.

- A well pump that doesn’t start, which might indicate an issue with the switch’s electrical contacts.

How To Reset Well Pump Pressure Switch?

Resetting your pressure switch can often resolve minor glitches. To reset, follow these steps:

- Turn off power to the pump at the breaker.

- Remove the cover of the pressure switch.

- Locate the reset lever or button, often marked as “ON/OFF” or “RESET”.

- Press or lift the lever/button to reset the switch.

- Restore power and check if the pump starts normally.

What Happens When A Pressure Switch Fails?

Pressure switch failure can lead to several issues:

- No water is delivered to your home.

- Overworked pump due to continuous running, risking burnout.

- Potential for over-pressurization and damage to the plumbing system.

How Often Should A Well Pressure Switch Be Replaced?

A well pressure switch doesn’t have an exact expiration date, but it’s wise to consider replacing it every: Usage LevelSuggested Replacement FrequencyLow to ModerateEvery 5-7 yearsHighEvery 2-4 years.

Conclusion

Dealing with well pump pressure switch issues can be daunting, yet it’s essential for a consistent water supply. Remember, regular maintenance prevents most problems. Should you face challenges, professional help is just a call away. Keep your system in check, and enjoy uninterrupted water flow at your fingertips.